Well, what can I say, we love our new vessel. When we purchased there was of course a punch list of things that needed addressed (see So It Begins), but overall they were very minor. Some of it was just getting things organized, investigating and documenting how things worked. We needed an Ice maker, and addl freezer room etc. You know.. those Big Things! lol. For those of you who have purchased a cruising vessel, you know these are all trivial. We have been blessed.

There are a few items that were a little more involved that needed addressed. First, the generator has issues starting from cold. needs several crank cycles to start up forcing an OC error on the Kohler. This one is currently being addressed. Second, we also have no easy heat options for the winter. By easy, I mean things that don’t require constant power. There are 4 reverse AC units on the vessel, which provide good heat, but only if you have short power, or run the Gen 24/7 which we hate doing. This led me to investigating several solutions. A popular option is adding a diesel hydronic furnace. Our previous vessel had this and we loved it. However, quotes were coming in around $30K-$40K to add this. ouch. But, I didn’t have an option… until…I thought about the issue a little differently.

Not too long ago a fellow Navigator / Seattle owner installed a system on his Navigator to address this very problem. (Ellie Yacht) At first, it didn’t click for me. I had envied his system, but to me it was more about hanging out all summer and barely having to run the Gen. Then one day the light bulb went off…that same system could also supply POWER for the reverse AC units while not plugged in. What is this system??? LiFEPO4 and some beautiful Victron equipment.

So, before going into my solution, here is a not so brief outline of batteries and how I came to selecting the LiFePO4 solution.

For those of you who have ever looked into batteries and suppling power to inverters, you know there are many options. Flooded Lead Acid Deep Cycle (FLA), AGM, Carbon Foam AGM, and more recently LiFEPO4 (Lithium Iron Phosphate). They all have their pros and cons for different uses. The traditional FLA are plentiful, and cheap, but they are heavy, life span is relatively short, and usable stored energy is small. To put it in perspective, a FLA battery (Group 27) may have 100 Ah (amp hours) available to it, but due to the construction of the battery, its only really usable from 100-60% charge w/o causing long term damage to the life of the battery, resulting in only 40Ah of available power. They are also sensitive to storing them at charge states less than 100%. Finally, they have a limited life span, typically 200-300 cycles. AGMs help in this space, and are less sensitive to storage charges. They also increase the available usage capacity beyond the Lead Acid, giving about 50% usable capacity for repeated use (now giving us maybe 50-60 Ah of usable power per battery). They also offer around double the charge cycles over the FLA counterpart. This helps to offset the additional cost of an AGM over FLA. There are also niceties like not having to deal with the dangers of the liquid acid portion of a FLA.

In recent years, alternatives have come up which improve on the AGM design including options like FireFly’s Carbon Foam AGM. The different chemistry allows for a larger discharge capacity (up to 80%), and removes the issue of sulfation which is what kills an AGM. This is caused by repeated storage at partial state of charge. This is a great improvement especially over the FLA deep discharge counterparts. This now could give us closer to 70-80 Ah of available power on a similar Gp27 battery. They also improve cycles to a reported 800-1000 cycles. The downfall is they are still very expensive, heavy and fairly large groups are needed for the power demanded.

And last but not least, LiFEPO4. While not “new”, they are just recently being used in more DIY systems. These batteries have been around now in transportation commonly for at least 20 years. Electric trucks and cars have been using them for at least that period with remarkable results. LiFePO4 have the ability to provide a large discharge capacity (80%), high density of power in a small package (group 27 of 138 Ah), and half the weight of the FLA counterpart. (110Ah of available power per battery… compared to the 40 of the FLA) Best of all, their longevity can provide for upward of 4000 charge cycles. This comes at a cost… They are pricey at 6-10 times the cost of a FLA. They also require great care in how they are charged and maintained. They are also sensitive to over and under charging, as well as the temperatures of where they are stored and used. A big positive is they can accept a HIGH rate of charge. They can accept 10x the amperage you could push into a FLA, allowing you to draw them low and then fill them back up in very quick fashion. Ultimately, the large capacity, longevity, small footprint, and ability to charge quickly won me over.

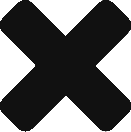

So… Back to my solution. I chose to go with a system of 12 – Valence U27-12xp batteries. These are 138 ah batteries that were originally used in electric truck and delivery vans in the early 2000’s. They can be found through various second hand markets for a fraction of what similar batteries go for new. Even at 15 years old, they are still around $500/ea, but this sure beats the $2000-$2500 for a similar new battery available today. The best part is, the chemistry of these could care less how old they are. Its all about how many cycles were on them, and were they stored properly over that time. The good news is, they all have little ecu’s on them which store and log their entire use history.. including how many cycles they have had and any time they were improperly stored or charged. I was able to source 12 of these that ranged from 25 cycles to 150 cycles all with a good history. This means worst case, I have 3800 cycles left! If I were to completely discharge and recharge them 100 times per year, I still have 38 years of life left on them! I keep all the batteries balanced and operating within safe limits through the use of a BMS (Battery Management System). I went with one from Muller Industries. I am still debugging a few little issues, but overall it seems to be a good solution. I am told they have a new internet configurable BMS coming out next year which would really make me happy as I hate the black box approach where I cant see and control things as i wish.

To maximize the ability to quickly charge and provide a high output of power to the inverter, I chose to configure these in a 48V system of 3 parallel groups of 4 batteries wired in series. This gives me 414 amp hours @ 48V (nearly 20KWh). When you think about usable range of 80%, this results in 330 Ah of usable energy. (nearly 16 kWh) Or, enough to supply an average 1600 watts output for 10 hours! On our vessel, we consume around 700 W minimum by just operating base systems. 2 of our AC units draw 1200W/ea (salon and Pilot House), and the two stateroom systems draw around 500W/ea. The water heater under full load draws 1500W.

Over the winter, the demands are higher. We are constantly running heat (cycling on and off), and are able to run about 5 hours during the day when everything is running, and a full 10 over the night with just the cycling of heaters in the staterooms. This is phenomenal in my eyes. In the summer, we don’t need Air Conditioning often in the salon etc, and just moderate usage in the Master stateroom as we don’t have port holes for ventilation. This will allow us to easily go an entire night / 12 hours with AC running and no Gen. The best part of this all is once the Gen fires up, the entire bank will be recharged in under 3 hours. We have the bank configured to accept up to 140a charge and the batteries love it. (I’ll get to it later, but the system is always monitoring the batteries and will Auto Start the Gen should they drop too low)

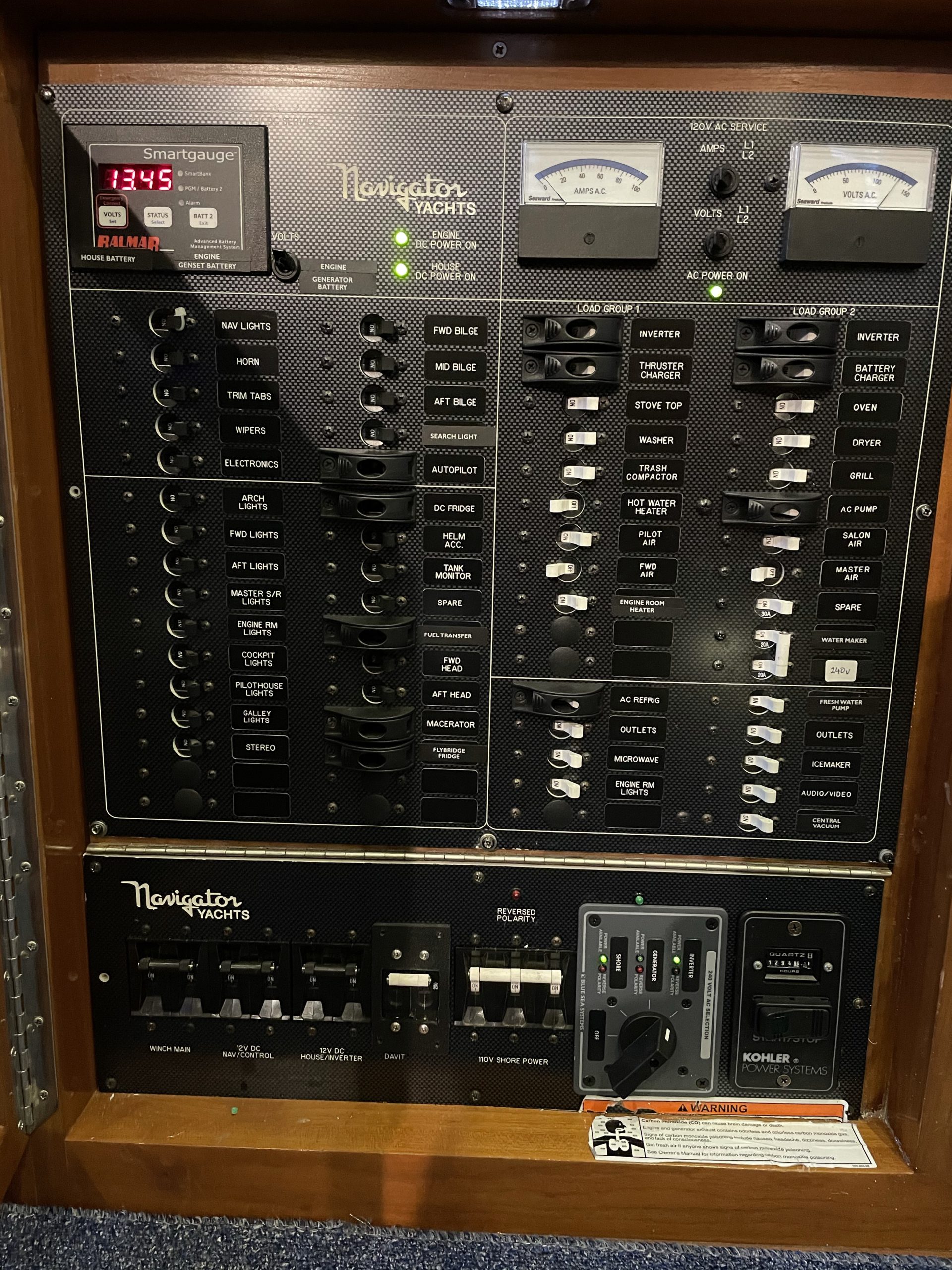

Now, to the design. Our boat is relatively new (2011), and has modern systems and batteries to start. it has 6 of the FireFly Carbon foam AGMs wired to a MagnaSign PSW inverter and that supplies power the 12V house loads as well as to most cabin outlets, refrigerators’ and freezers. There is the main galley refrigerator, 2 beverage refrigerators and a deep freeze. It is sized to handle those loads fairly well for an overnight draw. The main 110/220 panel is looking for 2 110v feeds that supplies 2 load banks with 110v of power from either Shore or Gen.

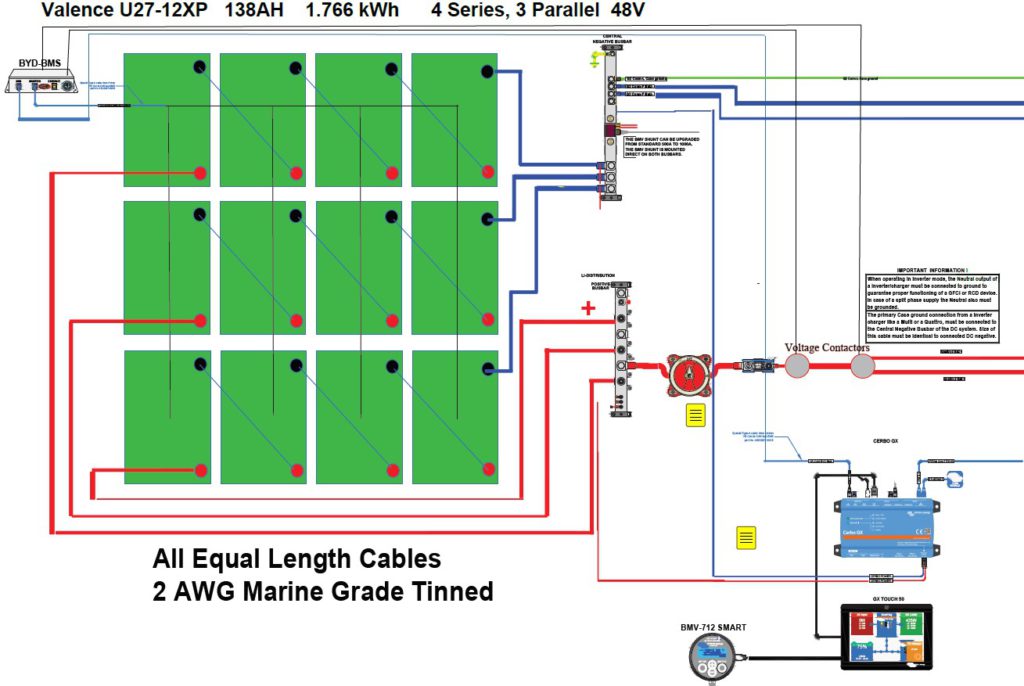

What I did is insert a 3 way power supply switch that allows me to feed the panel from either Shore directly, Gen, or through the inverter. This allows me to bypass the inverter system should there ever been an issue. This allowed me to allow the inverter to essentially power the entire boat, and effectively replaces the shore or gen with really no rewiring.

I chose Victron gear to do the inverting. They have high quality gear, that is designed for the technically inclined, and at price points that are tough to match. I first feed the inverter/charger which is a Quattro 48v 10KW inverter. Two real nice features for me is first it acts like a UPS (uninterruptable power supply) so when I plug/unplug from shore, or fire up the gen, the entire boat power never goes down during the switch overs. Second, it has the ability to assist when loads are high. For instance, lets say I am at a marina with only 30a /220v power service (I use a smart combiner to allow me to combine two 30a/110v opposite phase feeds which is all that is available at many marinas in the PNW). If I really want to run a lot of systems, it will over power that, and I will blow the breaker. However, the Quattro is smart enough to know when I am drawing more than 30a, and will pull power from the batteries to supplement the shore power as long as its needed. Once the load goes down, it will use leftover shore capacity to recharge the batteries. Both of these scenarios were things that drove me nuts with our previous vessel.

To simplify the power output into my panel to provide true split phase power, I run the power out of the Quattro and into Victron’s Autotransformer (100a). This device essentially creates the neutral leg, as well as compensates for unbalanced legs. Back to that 30a scenario. Normally that means I have 30a of power on each of my two 110v legs. Lets say however that my power demands 40a of power on 1 leg, and only 15a of power on the other. This usage would trip a breaker of one leg at shore under normal conditions… but the AutoTransformer actually takes the two input legs and combines them, and allows the total amperage to be shared as needed. In this scenario, it sends 40a and 15a to the respective legs. Super cool!

The Quattro is highly configurable as well, and allows me to setup custom charge patterns to protect my LiFePO4 batteries. For those with larger demands, these can be combined to provide 20/30/40 + KW of power.

Lastly, I added the Cerbo GX as well as the new color display to give a nice management interface to it all. This connects to all Victron equipment and allows me to view into it. It logs all the data, and gives me the ability to see and control items via the internet from anywhere in the world. It also is able to watch the battery bank, and Auto Start the generator when it see the bank getting too low, and shut it down once charged. This takes a big burden off of me to be sure I don’t accidentally drain my batteries too low. It also provides protection should I lose shore power when not at the boat. It will keep everything running should we experience an unexpected loss of power.

Here are the schematics I created for my system. The install turned out real nice. I have a nice lazarette under our galley which provided the perfect place to install all this equipment, without really sacrificing the valuable storage space needed.

Below are the install pics of the equipment and batteries. I built a custom aluminum frame to mount the Victron gear above a box that encloses one of the AC units. I mounted the monitoring gear above, and use the ability to remotely control these over the network to simplify the amount of wire running that was needed. On the opposite side of the lazarette I installed the batteries. I did my best to balance weight port to starboard and kept things pretty level. Note, since these are not a “wet” battery, they do not need to be enclosed in a box. All connections are properly protected and secured. The batteries are industrial level batteries with internal equalization, with fire resistance cases and are UL Certified and IP65 waterproof rated. I still have a little clean up to make my wiring a little more neat on the batteries, but overall its done and functioning.